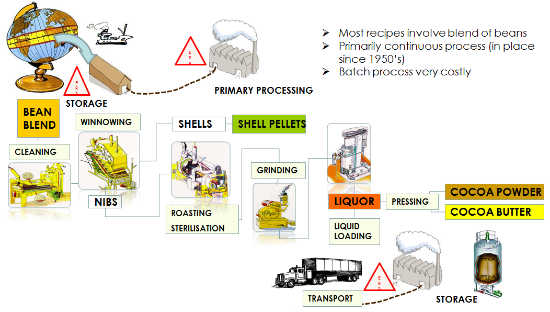

From bean to mass

In order to be used in the production of cocoa and chocolate products, cocoa beans are processed into cocoa mass (or liquor).

On arrival at the processing factory, the beans undergo a second quality inspection and are then cleaned, mixed into the desired blend, fragmented and stripped of their husks. What remains is the inner part of the kernel, called ‘nib’. The nibs are heat-treated to eliminate possible bacteria and subsequently roasted and ground into a liquid cocoa mass. The nibs may be alkalized before, during or after the roasting process. This determines the colour and taste of the cocoa mass, which, as an intermediate or semi finished product, is supplied to the chocolate industry and is also the basis for the production of cocoa powder and cocoa butter.

From mass to butter

Fat is pressed out of the cocoa mass under high pressure (up to 550 kg/sq.cm). The butter is subsequently filtered, to remove the last remnants of solid cocoa ingredients. The manufacturer supplies the cocoa butter in liquid form in tankers, or in solidified form in cardboard boxes. Upon request, cocoa butter can be made odourless by means of steam and vacuum extraction – the chocolate industry usually demands butter with a neutral taste. Cocoa butter is also used in the production of cosmetics and toiletries.

From mass to powder

What remains after the removal of the cocoa butter through pressing are cocoa cakes, disks with a thickness of approximately five centimetres. These cakes are broken up and ground into a fine cocoa powder. Each manufacturer supplies its own type of powder, with its own distinctive colour, aroma, pH-value (degree of acidity) and fat content. Since it contains the aroma, taste and colour of cocoa, powder is added to several food products for flavour and colour: biscuits, puddings, desserts, creams, filled chocolates, ice cream. When mixed with sugar and diluted with milk, it turns into a mild chocolate drink. It also provides the finishing touch for confectionery, truffles and cappuccino coffee, and new applications are regularly introduced.

From mass and butter to chocolate

Chocolate is made from cocoa mass, to which sugar, cocoa butter and, optionally, milk are added (white chocolate does not contain any cocoa mass, however). The resulting mixture is rolled and ‘conched’. Conching is a treatment whereby chocolate is kept in continuous movement to allow the cocoa mass to develop into a homogenous substance. This process also allows volatile acids to escape, whereby the aroma is improved. Conching lasts for a number of hours. The name originates from the shell-shaped container in which the treatment took place in former days (‘concha’ being the Spanish word for shell). Depending on the desired taste, other ingredients may be added.

Finally, the hot chocolate mass must be allowed to cool slowly. This process, called ‘tempering’, is important for the right crystallization of the cocoa butter. After tempering, the chocolate can be poured into any desired form and hardened. During the hardening process the volume of the chocolate is reduced, allowing the chocolate to come out of the mould automatically.

For a product to be defined as ‘chocolate, cocoa butter must be the product’s main source of fat – EU Directive 2000/36 only allows the addition of up to 5% of vegetable fats other than cocoa butter in the weight of the end product. Should this percentage be above 5%, the product may not be called chocolate, but rather ‘cocoa substitute’.